Application of Reactor Steam Heating in the Chemical Industry

In the chemical industry, the heating method of reaction vessels is crucial, and steam heating has become a favored choice for many enterprises due to its unique advantages. Today, let’s delve into the charm of steam heating in reaction vessels.

As an important equipment in chemical production, the heating effect of the reactor directly affects the quality and production efficiency of the product. The reason why steam heating stands out among many heating methods is mainly due to its high efficiency, stability, and ease of control.

Steam heating can quickly provide uniform heat to the reaction kettle, ensuring temperature stability during the reaction process. This is undoubtedly crucial for some temperature demanding chemical reactions. Compared to other heating methods, steam heating can better meet the temperature uniformity requirements of the materials inside the reaction vessel, thereby improving the quality and consistency of the product.

Meanwhile, the energy utilization efficiency of steam heating is relatively high. The steam generated by the electromagnetic boiler can effectively transfer energy to the reactor, reducing energy waste. In today’s environment that emphasizes energy conservation and emission reduction, this advantage makes steam heating more competitive in the chemical industry.

In addition, the operation and maintenance of the steam heating system are relatively simple. Through reasonable design and installation, automation control can be achieved, greatly reducing the need for manual intervention and improving production safety and reliability.

In practical applications, the combination of electromagnetic boiler steam heating the reaction kettle has brought many conveniences to chemical production. Electromagnetic boilers have the characteristics of high efficiency and environmental protection, which can quickly generate high-quality steam and provide a stable heat source for the reaction kettle.

In short, steam heating in reaction vessels plays an important role in the chemical industry. Its high efficiency, stability, and energy-saving characteristics, as well as its perfect combination with electromagnetic boilers, provide strong support for chemical enterprises to improve production efficiency, reduce costs, and ensure product quality. I believe that in the future chemical production, steam heating in reaction vessels will continue to play its advantages and promote the continuous development of the industry.

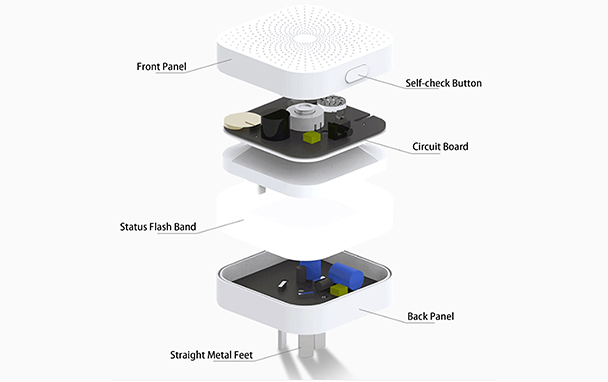

| Model | JT—KBI1 |

| Target Gas | Natural Gas (methane)/LPG |

| Sensor Type | Semiconductor |

| Overall Dimensions | 59mm’59mm’40mm |

optional for natural gas or LPG

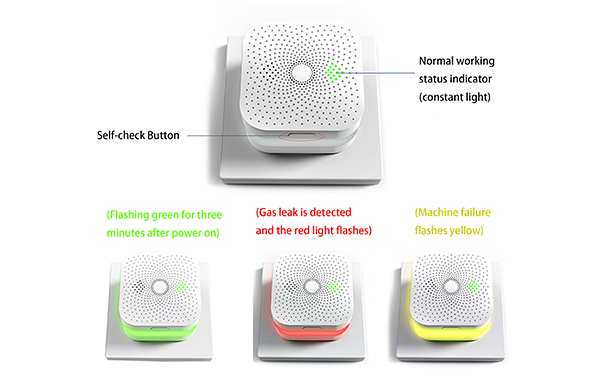

100% gas sensing platinum electrode,high resoution to avoid false alarm

visible and aduible alarm

lower power consumption,2kwh per year

up to 70dbalarm sound,ring waring light desig

It can be widely used in the city gas transmission and distribution pipeline, oil, petrochemical industry refineries, chemical plants, metallurgical industry, power industry and other places that may produce gas leakage.

City Lifeline

City Lifeline

City Lifeline

City Lifeline

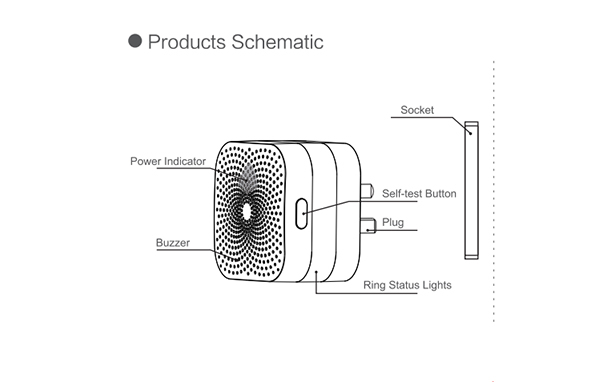

| Model | JT—KBI1 |

| Target Gas | Natural Gas (methane)/LPG |

| Sensor Type | Semiconductor |

| Overall Dimensions | 59mm’59mm’40mm |

| Sampling Method | Natural diffusion |

| Working Voltage | AC 90V — 260V |

| Range | 0—100% LEL |

| Warm—up Time | 180s ± 10s |

| Alarm Setpoint | 7% ± 3% LEL |

| Alarm | Visible and Audible alarm |

| Working Environmen | Temperature: —20 to 40℃ |

| Humidity: ≤ 95% RH (no frost) | |

| Alarm Volume | 70dB |

| Service Life | 5 years ( under normal working environment ) |

Electromagnetic steam generator is a new type of steam equipment that utilizes the principle of electromagnetic induction to convert electrical energy into thermal energy, thereby generating steam. This type of steam generator has the advantages of high efficiency, environmental protection, and energy saving, and has been widely used in industrial, medical, catering, and other fields.

Airradio natural gas detector is for natural gas.If there is gas at home,once the concentration of the detected gas reaches the dangerous value,the detector will send out the audible and visual alarm singal,prompting you to take effective measures quickly to eliminate the danger and effectively avoid the accidents such as fire and explosion.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: